Glass Thickness Calculator

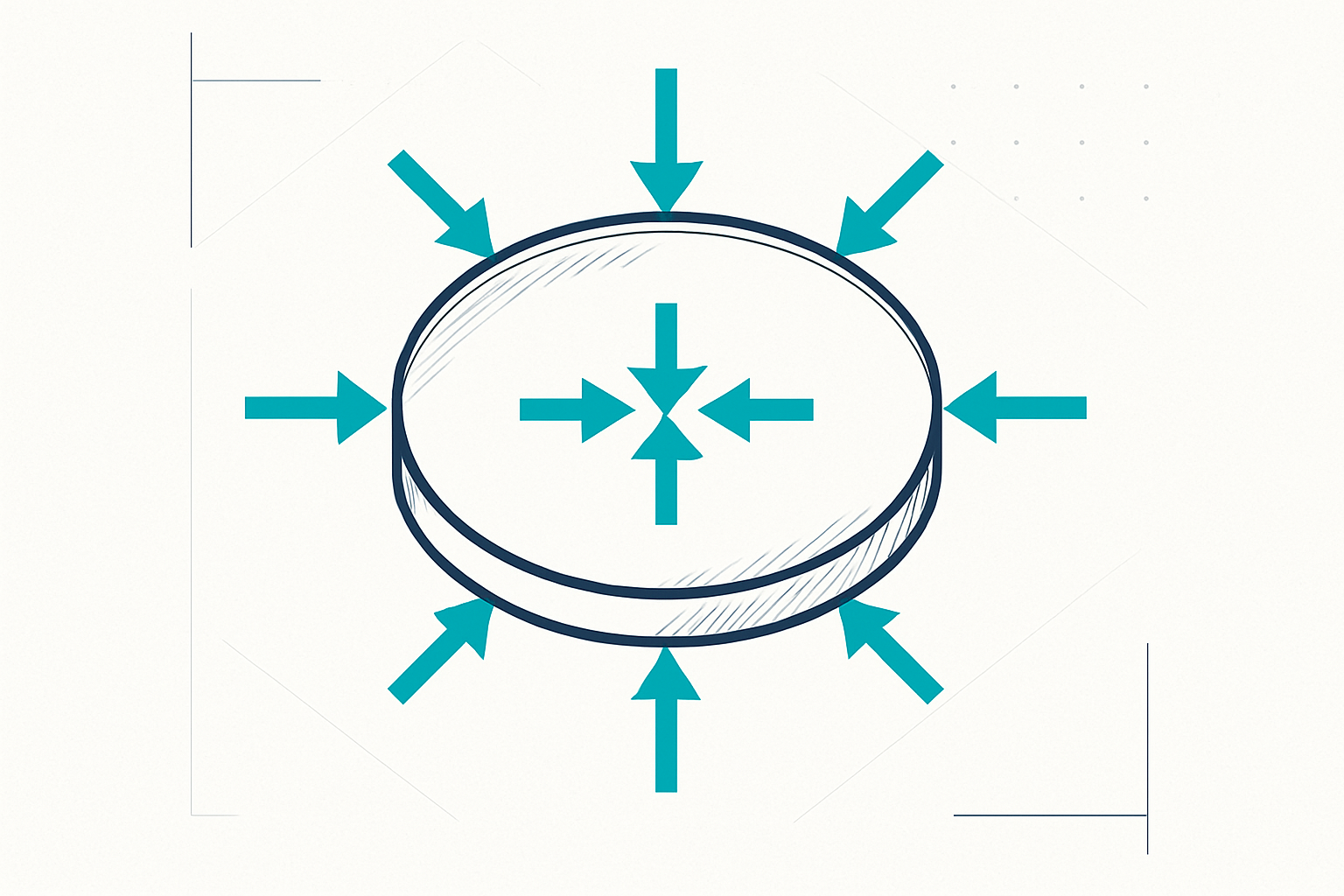

Engineering precision for circular glass discs under pressure

Calculate Required Glass Thickness

Determine the minimum thickness of circular flat glass discs needed to safely withstand pressure differentials. Based on engineering formulas from Roark's Formulas for Stress and Strain.

Precise Engineering Formula

Based on plate stress analysis and material properties

Real-Time Calculation

Instant results as you adjust parameters

Safety Factor Included

Configurable safety margins (4.0 - 6.0)

Input Parameters

Range: 10 - 300 mm

1 bar ≈ 14.5 PSI (1 atm)

MR = Modulus of Rupture (Design Tensile Strength)

Engineering Formula:

Thk = √(1.1 × P × r² × SF / MR)

Where: P = Pressure (PSI), r = Radius (mm), SF = Safety Factor, MR = Modulus of Rupture (PSI)

Calculation Result

Calculation successful

Minimum Required Thickness

≈ 0.210 inches

Design Recommendation

Always verify calculations with material certifications and apply appropriate safety factors for your specific application.

Technical Reference

Glass Properties

- •Borosilicate: MR = 7,000 PSI

- •Fused Silica: MR = 7,000 PSI

- •Safety Factor: 4.0 - 6.0

Unit Conversions

- •1 bar = 14.5038 PSI

- •1 MPa = 145.038 PSI

- •1 inch = 25.4 mm

Formula Details

- •Based on Roark's Formulas

- •Fixed edge boundary condition

- •Uniform pressure loading